Langlebigkeit ist eine strategische Produkteigenschaft für Geschäftskunden - kein Luxus. Für Distributoren, Einzelhändler und Produktmanager reduziert ein ausgereifter Mini-Thermodrucker Rücksendungen, Servicekosten und Markenschäden und erhöht gleichzeitig die Kundenzufriedenheit und den Umsatz über die gesamte Lebensdauer.

In diesem Leitfaden wird Aiyin, ein führender Hersteller von Thermodruckernsetzt die technischen Signale des Mini-Thermodruckers in Beschaffungsprüfungen um: Materialien, Kernsubsysteme, Prüfprotokolle und eine fünfminütige Musterbewertung, die Sie in der Fabrik verwenden können.

Externe Technik - die erste Verteidigungslinie

Oberflächenmaterialien und strukturelle Gestaltung verraten die Prioritäten eines Herstellers.

- Material des Gehäuses: ABS ist wirtschaftlich; PC/ABS-Mischungen erheblich Verbesserung der Stoßfestigkeit und Wärmestabilität. Höherwertige Mischungen widerstehen dem Vergilben und Versprödung wenn UV-Stabilisatoren verwendet werden.

- Plattenabstände und Toleranzen: Feste, gleichmäßige Nähte (<0,1-0,2mm) weisen auf Präzisionswerkzeuge und Formenkontrolle hin. Große oder ungleichmäßige Spaltmaße sagen das Eindringen von Staub und einen frühzeitigen Ausfall voraus.

- Verstärkte Strukturen: Suche nach Innenverrippung oder Opferpuffer - unverzichtbar bei eingesteckten, heruntergefallenen Geräten.

- Oberflächenbehandlung: Anti-Rutsch-Texturen und kratzfest (matt) Beschichtungen bewahren das Aussehen im täglichen Gebrauch und reduzieren "dead on arrival" Kosmetik Ansprüche.

Das Herzstück - Druckkopfqualität und -schutz

Der Druckkopf ist das primäre Verschleißkomponente eines beliebigen Mini-Thermodruckers.

- Heizelemente: Während alle verwenden Tonerde-BasenDie High-End-Versionen verfügen über eine dicke Glaskeramik Schutzglasur (Deckschicht). Diese Schicht bestimmt die "Pulsdauer" und die Beständigkeit gegen Abrieb durch Papierchemikalien.

- Präzise Ausrichtung: Der interne Rahmen muss Folgendes beibehalten vollkommen parallel Kompression zwischen Druckkopf und Walze über den Medienweg. Eine falsche Ausrichtung führt zu verblassten Rändern und ungleichmäßiger Dichte.

- Schutz vor ESD und Kontamination: Antistatische Maßnahmen und Silikon Staubdichtungen verlängern die Lebensdauer der Elemente drastisch. Fragen Sie nach dem Drucklebensdauer (z. B. 50 km oder 100 Millionen Impulse).

Mechanisches Design und kinetische Haltbarkeit

Mechanische Teilsysteme bestimmen die tägliche Zuverlässigkeit.

Papierweg und Rollen: Hohe Reibung Silikon Rollen verschleißen vorhersehbar über Temperaturenbilliges Gummi härtet aus und rutscht.

Abrissbirnen vs. Cutter: Die meisten Minidrucker verwenden gezackte Abrisskanten aus Edelstahl. Bei Modellen mit automatischen Schneidevorrichtungen sollten Sie auf selbstschärfende Metallklingen bestehen und nicht auf kunststoffummantelte Versionen.

Scharniere und Verschlüsse: Das Scharnier der Papiertür ist ein stark beanspruchter Punkt. Verstärkte Metallstifte und eine taktile "positive Sperre" klicken, deuten auf eine robuste Abdichtung und weniger Ausfälle in der Praxis hin.

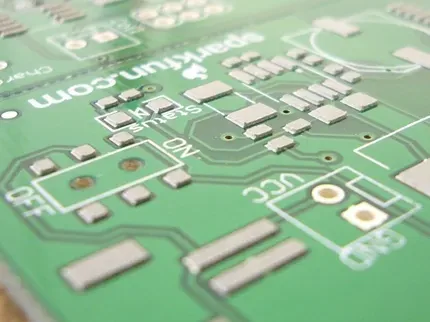

Interne Elektronik - unsichtbar, aber kritisch

Gut konzipierte Leiterplatten und Wärmemanagement verhindern viele latente Ausfälle.

PCB-Bestückung: Überprüfen Sie SMT-Präzision. Kalte Fugen und sichtbare Flussmittelrückstände (oder "tombstoning", ungleiche Kraftverteilung an beiden Enden des Bauteils führt dazu, dass es sich aufrichtet, was zum Versagen der Schaltung führt) mit vibrationsbedingten Ausfällen korrelieren.

Verstärkung des Verbinders: Lade-/Datenanschlüsse sollten verfügen über abgeschirmte Laschen, die durch die Leiterplatte gelötet sind (Durchgangslochverstärkung), oder sind "Mid-mount"-Stile. Oberflächenmontierte (SMT-only) Anschlusspads allein sind die #1 Ursache des physischen Ausfalls in tragbaren Geräten.

Wärmemanagement: Kupfer wird auf die Leiterplatte gegossenniederohmige Leiterbahnen, und ausreichende Wärmeabfuhr Verhinderung der Drosselung während kontinuierliche Charge Drucken.

Stromzuverlässigkeit und Batteriesicherheit

Die Qualität der Batterien ist ein wichtiger Faktor für die Benutzerfreundlichkeit und Sicherheit eines Mini-Thermodruckers.

- Einstufung der Zellen: Tier-1-Zellen halten wesentlich länger als minderwertige Alternativen. Erwarten Sie ~500 Zyklen für High-Tier-PacksZellen mit niedrigem Rang können sich abbauen, nachdem 200-300 Zyklen.

- Batterie-Management-System (BMS): Überladung, Überentladung und NTC-Thermoüberwachung sind nicht verhandelbar. Bestätigen Sie das Vorhandensein von BMS und Sicherheitszertifikate.

- Mechanische Fixierung: Die Zellen müssen mechanisch mit Klammern oder hochhaftenden Klebstoffen befestigteine "klappernde" Batterie ist ein Brandgefahr.

Umwelt- und Szenario-Resilienz

Ein angegebener Betriebsbereich ist nur sinnvoll, wenn er validiert ist.

Temperaturtoleranz: Überprüfen Sie sowohl die Druckleistung als auch das Verhalten des Akkus bei niedrigen/hohen Temperaturen. Qualitätsdrucker verwenden kompensierte Ladealgorithmen für kalte Umgebungen.

Eindringtoleranz: Auch wenn volle IP-Einstufungen selten sind, sollten Sie den Papierweg und die Tasten auf Staubschutz überprüfen.

Qualitätssicherung und globale Standards

Bescheinigungen sind hilfreich, aber nicht ausreichend.

- Bescheinigungen: CE, FCC, RoHS bestätigen die Einhaltung. Bestehen Sie auf UN38.3 (Batterietransport) und spezifischen MTBF-Laborberichten (Mean Time Between Failures) für professionelle Märkte.

- Werkseitige Prüfung: Falltests (1,2m-1,5m), Vibrationstests, und Burn-in-Tests sind wichtige QA-Praktiken.

Praktische Checkliste für den Käufer - Beurteilen Sie ein Muster in fünf Minuten

- Torsionsprüfung: Drehen Sie das Fahrgestell leicht - achten Sie auf Knarren. Knarren = schlecht strukturelle Verrippung.

- Konsistenz der Dichte: Drucken Sie einen durchgehend schwarzen Block. Weiße Streifen oder "Verblassen" an den Rändern deuten auf eine schlechte Ausrichtung oder minderwertige Druckköpfe hin.

- Port Stress: Stecken Sie ein Kabel ein und wackeln Sie vorsichtig daran. Jede Bewegung in der internen Buchse ist ein wichtiges Warnsignal.

- Scharnier-Zyklus: Öffnen und schließen Sie die Papiertür 20 Mal schnell; beachten Sie wenn die Verriegelung sicher bleibt.

- Gewicht-zu-Größe-Verhältnis: A dichteres Gefühl zeigt oft an interne Abschirmung, bessere Batterien, und Metallverstärkung.

Schlussfolgerung

Die Verarbeitungsqualität von Mini-Thermodruckern ist ein messbarer Wettbewerbsvorteil. Für Händler und Markeninhaber vermeidet die Angabe der Haltbarkeit im Vorfeld nachgelagerte Kosten und schützt den Ruf. Passen Sie die Widerstandsfähigkeit des Mini-Thermodruckers an den jeweiligen Anwendungsfall an - Kinderspielzeug erfordert Stoßfestigkeit, Geräte für den Außeneinsatz brauchen eine hohe Lebensdauer und eine robuste Batterie.

Über Aiyin

Aiyin ist ein führender Hersteller von Mini-Thermodruckern anerkannt für zuverlässige Leistung, innovatives Design und hohe Produktionsstabilität. Wir Angebot Großhandel mit Mini-Thermodruckerzubehör und bauen kundenspezifische Thermodruckerlösungen die auf verschiedene Branchen zugeschnitten sind, von Einzelhandel und Logistik bis hin zu persönlichen Druckanwendungen.

Unser Unternehmen verfügt über in- und ausländische Vertriebszentralen in Xiamen und Shanghai, China. Die gesamte industrielle Kette ist global angelegt und deckt mittlerweile mehr als 90 Länder und Regionen ab.

Die Produktpalette von Aiyin umfasst und bietet:

- Etikettendrucker für Haus, Büro und Logistik

- Tragbare Fotodrucker für Kinder und kreative Anwender

- Maßgeschneiderte Etikettenlösungen für Markenpartner