Las impresoras térmicas parecen sencillas y fáciles de manejar, pero si comete un error, puede causar grandes problemas. No piense que con imprimir unas pocas etiquetas y recibos es suficiente. Para decírselo, como fabricante líder de impresoras térmicas, este no es un trabajo de "pulsar un botón". Muchas personas, ya sean nuevas o experimentadas, cometen algunos errores de bajo nivel, que dan lugar a malos resultados de impresión, desperdicio de materiales e incluso daños en el equipo. He aquí cinco errores comunes que puede cometer. No espere a que algo salga mal para lamentarlo.

⚠️ Error 1: Elegir el tipo incorrecto de impresora térmica

¿Lo sabía? Existen dos tipos de impresoras térmicas. Diferentes entornos y necesidades requieren máquinas diferentes. Si eliges la equivocada, tendrás un gran problema.

❌ ¿Qué puede salir mal?

- Al imprimir etiquetas para la cadena de frío con impresoras térmicas directas, las etiquetas se borran rápidamente.

- La impresión de etiquetas sencillas de envío a corto plazo con impresoras de transferencia térmica desperdicia cintas y tiempo innecesarios.

✅ ¿Qué hacer?

- Impresoras térmicas directas: adecuadas para imprimir etiquetas de corta duración, como etiquetas de envío, recibos o códigos de barras temporales.

- Impresoras de transferencia térmica: mejores para imprimir etiquetas duraderas y de larga duración, como etiquetas de inventario, muestras de laboratorio, etiquetas para exteriores, etc.

¿No está seguro de cuál elegir? Hable con el proveedor o fabricante y cuéntele primero sus necesidades reales, no sólo el presupuesto. Si tus necesidades son especialmente exigentes, puede que tengan que personalizar productos para usted.

⚠️ Error 2: Utilizar la combinación incorrecta de etiquetas o cintas

La impresión por transferencia térmica no es algo casual. La impresora, la cinta y la etiqueta deben estar correctamente adaptadas; de lo contrario, la etiqueta se verá borrosa, el código de barras será ilegible o incluso no se pegará con firmeza.

❌ Problemas comunes:

- Cinta de cera + etiqueta PET: la tinta no se pega.

- Cinta de resina + etiqueta de papel de baja calidad: la etiqueta se quema, y el coste se desperdicia.

- Adhesivo incompatible: la etiqueta se desprende en un entorno refrigerado.

✅ ¿Cómo solucionarlo?

- Para etiquetas generales de oficina y venta al por menor, utilice cinta de cera + papel estucado o sin estucar.

- Para etiquetas de durabilidad media (como las de almacén o logística), utilice cinta de resina de cera + papel estucado o etiquetas sintéticas.

- Para entornos extremos (como exteriores), utilice cinta de resina + etiquetas de PET o polipropileno.

¿Quiere ahorrar dinero? Pida a su proveedor de impresoras una tabla de compatibilidad de materiales, que puede ahorrarle tiempo y miles de dólares en residuos.

⚠️ Error 3: Descuidar el mantenimiento y la limpieza de la impresora

No piense que la impresora es un gran problema y lo ignore. Omitir la limpieza y el mantenimiento rutinarios desgastará el cabezal de impresión y afectará a la calidad de impresión.

❌ Síntomas:

- Impresión borrosa o descolorida

- Códigos de barras incoherentes

- Etiquetas atascadas o desalineadas

✅ Las mejores soluciones:

- Utilice las herramientas recomendadas por el fabricante para eliminar los restos de etiquetas o el polvo.

- Mantenga limpio el interior de la impresora para evitar que se acumulen restos de cinta o adhesivo.

- No toque el cabezal de impresión directamente con las manos: las manchas de aceite en las manos afectarán a la calidad de impresión.

Para su comodidad y eficacia, debemos recordarle que un mantenimiento regular puede alargar la vida de su impresora en 30%-50%, y sólo le llevará unos minutos.

⚠️ Error 4: Utilizar materiales de baja calidad o caducados

Las etiquetas baratas y las cintas de terceros pueden parecer un "buen negocio", pero a la larga, las consecuencias son algo más que un despilfarro.

❌ Lo que puede ocurrir:

- Las etiquetas se caen o destiñen

- La mala legibilidad de los códigos de barras afecta al escaneado

- Atascos de etiquetas debidos a un corte incorrecto o a núcleos no coincidentes

- Los adhesivos caducados pueden tener fugas y dañar los componentes internos

✅ Consejos de expertos:

- Utilice etiquetas y cintas certificadas por el fabricante.

- Mantenga los soportes secos y frescos cuando los guarde, y evite la humedad o la decoloración.

- Especialmente en las industrias médica, farmacéutica o alimentaria, preste siempre atención a la fecha de caducidad de las etiquetas y al rendimiento del adhesivo.

Los consumibles de alta calidad son caros, pero protegen el hardware y mantienen la estabilidad del flujo de trabajo. Pero merece la pena para quienes quieran mantener o mejorar la calidad de sus productos.

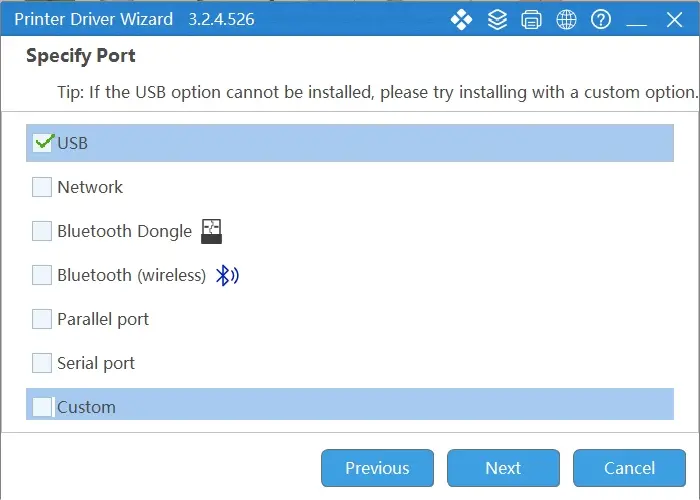

⚠️ Error 5: Ignorar los ajustes de software y calibración

Por muy inteligente que sea una impresora térmica, seguirá fallando si no se configura correctamente. No piense que estos ajustes son innecesarios. Si ignora estos detalles, a menudo se encontrará con diversos problemas.

❌ Problemas comunes:

- La impresión de la etiqueta no está centrada o falta

- El efecto de impresión es demasiado oscuro (quemado) o demasiado claro

- Error de tamaño de etiqueta o de detección de huecos

- No se puede escanear el código de barras debido a un desajuste de PPP

Soluciones:

- Ajuste el brillo de impresión en función de la combinación de cinta y etiquetas.

- Calibre el sensor de etiquetas cada vez que cambie de material.

- Utilice un software de diseño de etiquetas fiable (como BarTender, ZebraDesigner, NiceLabel).

- Asegúrese de que la resolución DPI establecida por el controlador y el archivo de etiquetas es correcta.

Una configuración correcta puede garantizar la claridad de las etiquetas, reducir los atascos de papel y los residuos, especialmente en el caso de las líneas de producción eficientes. Y nosotros AiyinAdemás de fabricar impresoras térmicas e impresoras de transferencia térmica, ofrecemos soporte de controladores y software para facilitarle el uso de nuestros productos.

🔍 Conclusión: Atención a los pequeños detalles

Las impresoras térmicas son una ayuda indispensable en el trabajo, pero no es tan fácil utilizarlas bien. Los errores mencionados pueden parecer pequeños, pero si se ignoran, pueden acarrear grandes problemas.

Acuérdate:

- Elija la impresora adecuada

- Combinar los materiales adecuados

- Limpieza y mantenimiento periódicos

- Utilice los consumibles adecuados

- Configurar correctamente el software

De este modo, no sólo ahorrará dinero y reducirá el tiempo de inactividad, sino que también se asegurará de que todas las etiquetas sean claras, escaneables y duraderas.

💡Acerca de Aiyin

Se preguntará por qué sabemos tanto de eso. Porque somos una fabricante líder de impresoras térmicas que posee conocimientos profesionales y está dispuesta a resolver cualquiera de sus problemas en el aspecto de las impresoras térmicas y las impresoras de transferencia térmica.

No sólo hemos ofrecido servicio personalizado para sus demandas especiales, pero también asistencia para controladores y software para que su trabajo sea más cómodo. No dude en ponerse en contacto con nosotros para recibir sugerencias de expertos.