Good thermal prints aren’t an accident — they’re the result of the right media, clean hardware, correct settings, good artwork, and sensible storage. Poor print quality costs time and money: unreadable barcodes, reprints, frustrated customers, and accelerated wear on your printers.

In this article, Aiyin, a leading thermal printer manufacturer, breaks down the top five factors that affect thermal print quality, shows how to diagnose each, and gives practical fixes you can apply today.

Factor 1: Media Quality — paper, labels, and ribbons

Why it matters: The substrate and its coatings determine how heat turns into dark marks. A poorly formulated thermal paper or the wrong ribbon will lead to poor thermal print quality, like pale prints, smearing, or heavy printhead deposits.

What to check

- Paper type: direct-thermal paper vs. synthetic (PET / PP) vs. thermal-transfer stocks.

- Coating: active coating uniformity, topcoat presence (for abrasion/moisture resistance).

- Ribbon match (for thermal-transfer): wax / wax-resin / resin — each pairs to specific substrates.

- Caliper (thickness): affects roll length and heat transfer behavior.

Symptoms of bad media

- Faint or uneven blackness; banding across prints.

- Prints that smear with light rubbing or solvents.

- Rapid accumulation of residue on the printhead (causing white lines).

- Barcodes failing scanner tests.

Fixes & best practice

- Use media and ribbon combinations certified by your printer supplier.

- Request technical data sheets (activation temp, coat weight, caliper) and run supplier samples.

- Standardize a small set of SKUs across your fleet to avoid mistakes.

- For high-handling labels, choose top-coated or synthetic media; for mobile printers, use high-sensitivity paper.

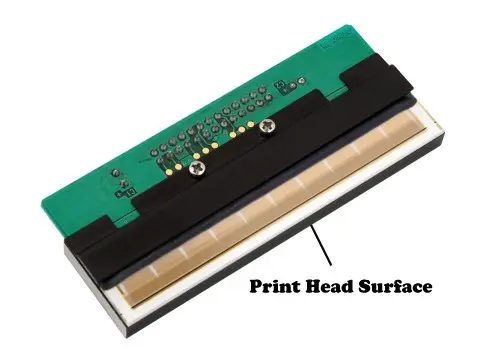

Factor 2: Printhead Condition & Maintenance

Why it matters: The printhead that creates the dots is affecting thermal print quality. Any dirt, adhesive, or worn element equals missing dots, banding, or inconsistent contrast.

How to detect problems

- Print a diagnostic pattern (many printers print a dot grid/test page).

- Inspect for white stripes, missing columns, or intermittent dark spots.

- Magnifier inspection of the head will show residue or scratches.

Routine maintenance (practical cadence)

- Daily: quick visual check and wipe in dusty or mobile environments.

- Every media change: clean the printhead and platen roller with isopropyl alcohol or manufacturer-approved wipes.

- Weekly / high-use lines: deeper cleaning and inspection.

- When you see the first signs: stop, clean, re-test — don’t run long batches.

Replacement signals

- Persistent dead elements after cleaning, or physical scratches — time to replace the head.

- Track prints-per-head and reprint rate as operational KPIs to predict replacements.

Factor 3: Printer Settings & Resolution (Darkness, Speed, DPI)

Why it matters: Darkness (heat), print speed (ips), and resolution (DPI) must be balanced for clear text, sharp graphics, and scannable barcodes.

Common misconfigurations

- Too high darkness: dense prints, but increased head wear and possible smearing.

- Too low darkness or too high speed: faint prints, lost dots.

- Wrong DPI for artwork: small text or dense barcodes printed at 203 DPI will blur.

How to optimize

- Start with manufacturer presets for your media, then run a settings matrix: vary darkness and speed in controlled steps to find the best trade-off.

- Match DPI to use case:

- 203 dpi for receipts, shipping labels, and general barcodes.

- 300 dpi for small text, tighter barcodes, logos.

- 600 dpi for microtext/jewelry or tiny component labels.

- Lock profiles per media/template to avoid accidental operator changes.

- For thermal-transfer, ensure ribbon tension and platen pressure are correct

Factor 4: Artwork & Barcode Design

Why it matters: The best hardware won’t fix a poorly prepared file. Barcodes, fonts, and images must be designed with printing realities in mind. This is the most easily overlooked point that affects thermal print quality.

Design rules

- Barcodes: calculate the correct module width for your target DPI. Too small a module at low DPI will cause unreadable code. Include required quiet zones and avoid scaling barcodes non-uniformly.

- Fonts: use clean sans-serif fonts; avoid hairline or decorative fonts for small sizes. As a rule of thumb, don’t use fonts smaller than the minimum legible size for your DPI (e.g., avoid <6 pt at 203 dpi).

- Graphics: prefer vectors for logos; rasterize at target DPI if needed. Don’t upscale low-resolution bitmaps.

- Color & contrast: thermal prints are monochrome—designed for optical contrast, not color.

Verification

- Use a barcode verifier (ANSI/ISO grades) for mission-critical labels. Visual checks are not enough.

Factor 5: Environment & Handling (Storage, Temperature, Humidity)

Why it matters: Heat, light, chemicals, and poor storage degrade thermal coatings and adhesives, causing fading, smudging, or label failure long before their intended life.

Key controls

- Storage: 15–25°C, 30–50% RH; keep rolls in original packaging and out of sunlight. FIFO inventory.

- Avoid contact between thermal paper and PVC or plasticized films (plasticizers migrate and can ruin prints).

- Field handling: don’t touch the printed face; use gloves when necessary. Condition rolls after cold transit to prevent condensation.

- Printer placement: away from direct sunlight or heat sources and, if needed, in dust-protected enclosures.

Symptoms of environmental issues

- Batch-level fading or yellowing.

- Adhesive failure in cold or damp conditions.

- Increased printhead fouling from contaminated stock.

Troubleshooting Checklist (5-minute triage)

- Media test: print on a certified sample roll — are prints still poor? If yes, the media are likely to be blamed.

- Head check: run diagnostics; clean the printhead and re-test.

- Settings sweep: print at default preset; try +1/-1 darkness and slower speed.

- Artwork check: print a vector-based test file with known barcode dimensions.

- Environment check: confirm storage/ambient conditions, and recent roll handling.

If the issue persists after all five checks, turn to supplier support with your test results for saving your thermal print quality (sample prints, settings used, and printer logs).

Conclusion

Thermal print quality is multi-factorial. Start by identifying the weakest link and correcting it. Standardize media and settings, keep a simple maintenance rhythm, and verify barcodes with a verifier for critical workflows. Do that and your labels will be sharp, scannable, and reliable — saving money and avoiding headaches.

About Aiyin

At Aiyin, a leading thermal printer manufacturer, we are devoted to providing thermal printers with high thermal print quality for our clients, covering a wide range of industries. Moreover, we are offering custom thermal printer solutions according to the needs of your business types to help your business.

We are confident that our products and solutions are the most suitable ones for your needs. Contact us for more information now!