If your warehouse, production line, or retail operation still prints labels manually or via one-off desktop jobs, you’re leaving speed, accuracy, and visibility on the table. Integrating thermal printers with your ERP or WMS turns printing from a disconnected task into an automated, auditable part of your operational workflow.

Expert insights from leading thermal printer manufacturer Ain. Five key benefits of integrating thermal printers with ERP/WMS systems.

Automated, Error-free Labeling

The problem today:

Operators manually enter or copy-paste product details into label software, or someone prints labels from a desktop and carries them to the line. Manual steps introduce typos, wrong product codes, wrong lot numbers, and inconsistent templates

What integration does:

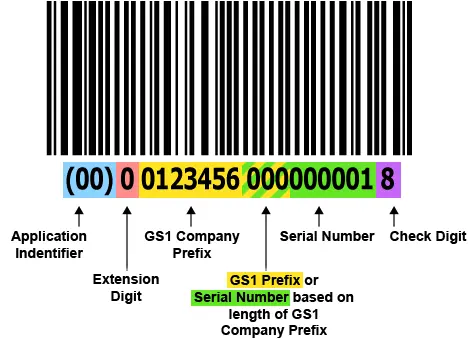

When your ERP/WMS triggers print, label data is generated programmatically from the master data source. The system injects live variables (SKU, bin location, serial number, batch number, production date, expiry, customer ID) into pre-formatted templates and prints directly to the destination printer.

Business impact:

- Eliminates human transcription errors, boosting first-scan barcode read rates.

- Speeds label generation (no wait for human input).

- Handles dynamic labels (e.g., multiple languages, shipping directives, weight-based labels)

On the pack line, when the order is picked and checked in the WMS, the system generates and prints the carton label with the correct GS1-128 barcode, carton weight, and destination — touch-free. No rekey, no mislabel.

Real-time Inventory Accuracy & Traceability

The problem today:

Paper labels applied later or posterior updates cause the system’s inventory image to lag behind reality. That creates stock discrepancies, mis-picks, and recall blind spots.

What integration does:

Print-and-tag processes become atomic transactions: the system records the print transaction (and associated unique identifiers) when the label is printed and put on at the same time. That gives one source of truth for location, ownership, and state transitions (e.g., picked → packed → shipped).

Business impact:

- Improved inventory accuracy — fewer cycle-count mistakes.

- Improved traceability — instant mapping from product to batch/serial number to shipment

- Simplified recalls/quality investigations — locate and quarantine affected lots quickly.

- Reduced time-to-trace for a batch/serial (hours → minutes)

- Inventory accuracy improved

Faster Order Fulfillment & Fewer Fulfillment Errors

The problem today:

Manual or semi-automatic printing creates bottlenecks: operators wait on print jobs, networks grind, or labels get printed in batches off-line and then get mismatched at packing.

What integration does:

ERP/WMS-triggered printing synchronizes label printing with the order-filling process. The system can queue and batch prints intelligently, route jobs to the closest printer, and ensure label templates are the correct size for the carrier, customer, or regulation demands.

Business impact:

- Lowered cycle times: decreased waiting, higher throughput

- Lower pick/pack error rates: scanner validation and printed labels that precisely match the order.

- Improved SLA(Service Level Agreement) compliance: faster packing and dispatch reduces late shipments.

Compliance & Standardized Labeling

The problem today:

Each site or operator uses a different template, producing nonstandard labels that fail audits or are not GS1/industry compliant (medical, food, chemicals).

What integration does:

Standards are imposed by centralized templates and rule-based label construction: correct symbology, required human-readable text, expiry format, regulatory messages, and localized messages. Templates can be version-controlled and centrally managed

Business impact:

- Audit-ready labelling across sites and regions.

- Fewer noncompliance events are costly in regulated industries.

- Streamlines international operations: the system enforces local regulations automatically.

Compliance example:

Pharma clients, at times, require GTIN, batch, and expiry in specific formats. ERP-driven templates guarantee those fields get printed correctly each time, reducing regulatory risk significantly.

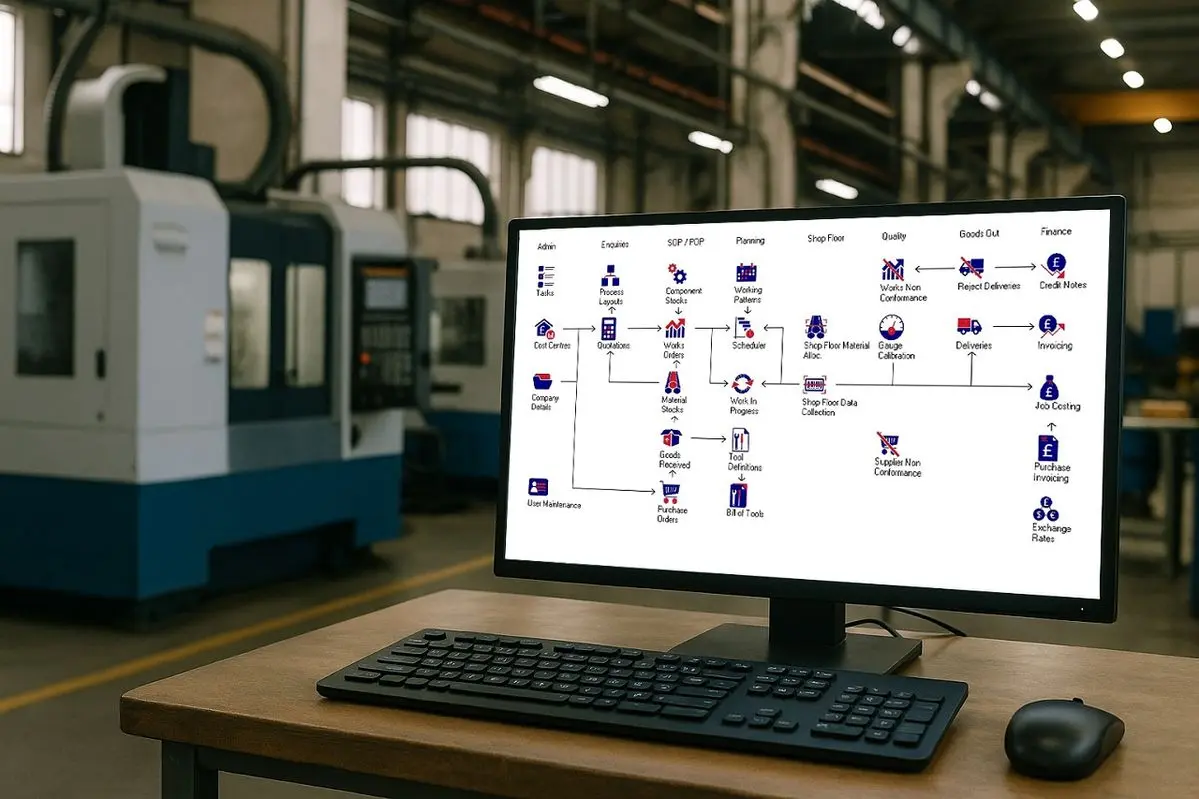

Centralized Management & Analytics

The problem today:

Printer fleets are islands unmanaged: firmware is different, drivers are outdated, consumable usage is unknown, and failures only become apparent when an operator creates a ticket.

What integration does:

An integrated platform (print server, middleware, or IoT-enabled printers) allows for centralized management: template deployment, driver/firmware management, usage reporting, and device health telemetry (error logs, head temp, roll length remaining, etc.)

Business impact:

- Save support and admin costs with centralized updates and remote troubleshooting.

- Data-driven inventory management: predict consumables usage and prevent stockouts.

- Preventive maintenance: detect rising error rates and act before catastrophic failure occurs.

Metrics to analyze:

Prints per site/day

SKUs consumed per day

Printer uptime and mean-time-to-repair (MTTR)

Common Pitfalls & How to Avoid Them

Poor architecture choice: Avoid choosing a single-site desktop model if scaling out to multiple sites is planned. If the printer is bound to a single computer, other terminals cannot directly call printing tasks and require additional configuration for sharing or remote printing, which increases complexity. Use middleware or the cloud for multi-site capability.

Ignoring offline situations: For remote locations, the network of remote warehouses or sites may be unstable, and ERP/WMS systems may not be able to send print tasks in real-time. If there is no local queuing mechanism, tasks may be lost or fail, resulting in the inability to print labels, shipping orders, etc., promptly. Make sure local queuing and retry logic

Too elaborate templates: Intricate raster graphics hold up rendering and lead to bottlenecks. Favor vector text and system-generated barcodes.

Insufficient testing: Always verify barcode grades and template printing on the particular printer model and media used.

No monitoring: You will not realize there is a systemic problem until an operational failure. Please do centralize logs and alerts.

Conclusion

Integrating thermal printers with ERP/WMS automates labeling, reducing errors and boosting efficiency. It ensures real-time inventory accuracy and faster, more reliable order fulfillment. Centralized management and standardized templates improve compliance and operational visibility. Avoiding common pitfalls guarantees a scalable, dependable printing workflow that supports business growth.

Aiyin, A Reliable Thermal Printer Supplier/Manufacturer

Aiyin is a leading thermal printer manufacturer, specializing in high-quality thermal printers that deliver reliable, fast, and precise printing solutions for retail, logistics, hospitality, and other business applications. We provide custom thermal printer solutions, offering flexible OEM and ODM services to help brands develop tailored printing devices that stand out in the market. Partner with Aiyin today to enhance your business with professional, customized thermal printing solutions.